Please scroll down for all course descriptions

please click HERE if you'd like to read our most recent newsletter

- 2024 craft classes schedule -

April 15 - 17, 2024 Classic Bentwood Firewood Carrier/Holdall; fundamental hand-tool skills & green woodworking

- long weekend/3 days, level 1, + $ 25 materials fee

April 24 - 28, 2024 Tool-making for Woodworkers with Blacksmith Lucian Avery; blacksmithing, metal working, tool making - 5 days, level 2+, + $ 40 materials fee

May 4 - 11, 2024 - Make a Chair From a Tree; fundamental green woodworking skills - 8 days, level 2+ or 3, + $ 55 materials fee

- May 12th to June 9th, MCCS MAINE BUG BREAK ! -

June 10 - 14, 2024 - Hand Hewn Greenwood Bowls - 5 days, level 2+, $ 25 materials fee

June 20 - 23, 2024 - Easy-Peasy Chair Making, Bill Coperthwaite's 4 board chair; fundamentals of hand-tool use & design - 4 days, level 1, $ 75 materials fee

June 29 & 30, 2024 - Small Greenwood Projects weekend; fundamental hand-tool skills & green woodworking

- 2 days, level 1, no materials fee

July 7 - 13, 2024 - Welsh Windsor Stick Chairs; hand-tool chair making - 7 days, level 2+ or 3, + $ 120 materials fee

July 19 - 21, 2024 - Hanging Lidded Salt Box; fundamental handcraft skills - 3 days, level 1, + 15 materials fee

July 29 to August 3, 2024 - Maine Gum Boxes & Decorative Chip Carving with Kenneth Kortemeier & Daniel Clay

- 6 days, level 2, + $ 25 materials fee

August 12 to 16, 2024 - Carve your Magic Loving Gift - the Swedish Folk Art Tradition of the Carved Distaff with guest instructor Jögge Sundqvist; handcraft skills, precision carving & knife grips - 5 days, level 1, + $20 materials fee - tuition for this class is $ 200 per day

August 24 - 29, 2024 - Small Coopered Wooden Buckets; hand-tool skills & design - 6 days, level 2, $ 45 materials fee

September 14 - 18, 2024 - American Folk Art - Ornate Carved Tramp Art Box; hand-tool skills & design - 5 days, level 1, + 45 materials fee

- tuition per day is $145 for all classes taught by Kenneth.

- Lucian Avery's Tool Making for Woodworkers tuition is $165 per day.

- Jögge Sundqvist's class is $200 per day tuition.

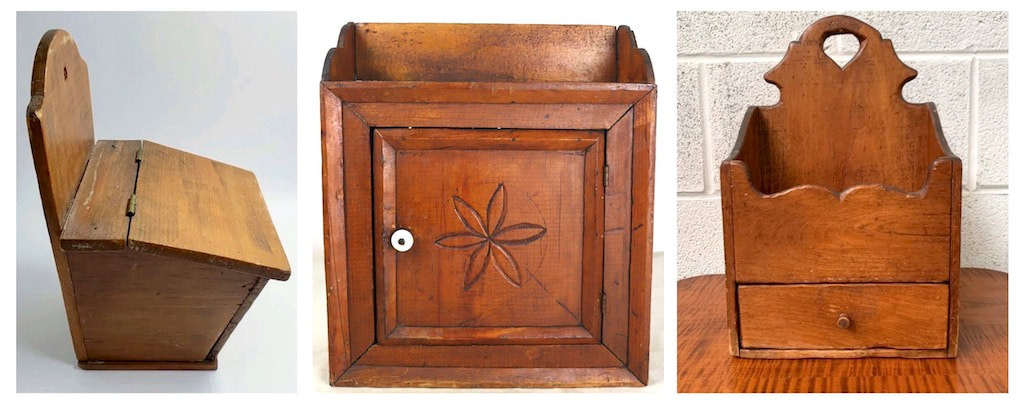

American folk art examples

Please get in touch with us via email if you are planning to register for a class!

- class descriptions for 2024 -

- finished for 2024 -

1. Classic Bentwood Firewood Carrier & Holdall; fundamentals of hand-tool use and green woodworking

April 15, 16 & 17th, 2024 - 3 days

exertion level - 1

materials fee - $ 25.00

$ 435 + $ 25 = $ 460.00 total

This three day/long weekend class is an excellent introduction to hand-tools and green woodworking. Students will learn how to use essential hand-tools and what it’s like to work directly with a tree to make an elegant, useful carrier and holdall.

We generally use these carriers for firewood at our house, but one can also hold items such as newspapers, towels, magazines, kindling, etc.

This project is based on an ancient Chinese firewood carrier pictured in the 1937 book “China at Work”. Several US green woodworkers that we know of have added to and been inspired by this design. For example, Drew Langsner included it as a project in his 1987 book, “Green Woodworking" and Peter Galbert produced a video with Lie-Nielsen Toolworks in 2017 called “Making a Firewood Carrier”.

A tremendously useful project on several fronts, most especially in terms of the range of foundational skills that can be learned in making it.

Skills learned:

- boring holes at predetermined angels with a hand bit and brace

- making mortise & tenon joinery by hand

- riving with a froe

- squaring wood to a required dimension with an axe and drawknife

- steam bending green red oak

1. Classic Bentwood Firewood Carrier & Holdall; fundamentals of hand-tool use and green woodworking

April 15, 16 & 17th, 2024 - 3 days

exertion level - 1

materials fee - $ 25.00

$ 435 + $ 25 = $ 460.00 total

This three day/long weekend class is an excellent introduction to hand-tools and green woodworking. Students will learn how to use essential hand-tools and what it’s like to work directly with a tree to make an elegant, useful carrier and holdall.

We generally use these carriers for firewood at our house, but one can also hold items such as newspapers, towels, magazines, kindling, etc.

This project is based on an ancient Chinese firewood carrier pictured in the 1937 book “China at Work”. Several US green woodworkers that we know of have added to and been inspired by this design. For example, Drew Langsner included it as a project in his 1987 book, “Green Woodworking" and Peter Galbert produced a video with Lie-Nielsen Toolworks in 2017 called “Making a Firewood Carrier”.

A tremendously useful project on several fronts, most especially in terms of the range of foundational skills that can be learned in making it.

Skills learned:

- boring holes at predetermined angels with a hand bit and brace

- making mortise & tenon joinery by hand

- riving with a froe

- squaring wood to a required dimension with an axe and drawknife

- steam bending green red oak

2. Tool-making for Woodworkers with Vermont blacksmith Lucian Avery (& Kenneth Kortemeier)

April 24th - 28th, 2024 - 5 days

exertion level - 2

materials fee - $ 40.00

$ 825 + $ 40 materials fee = $ 865.00 total

- tuition for this class is $165 per day (as opposed to our usual $145 per day), so that we may pay our guest instructor appropriately and cover his travel costs to Maine

Lucian Avery is a gifted tool maker and blacksmith from Vermont, and he’s a patient and masterful teacher as well. This will be the second offering of this excellent class - last year we had a great time immersed in the vital elements of fire, metal and water.

The list of tools made in 2023 included a center punch, scratch awl, screw driver, scribe, sloyd knife with birch bark sheath and a gouge, plus there was time for some free-form work at the tail end of the class.

We will explore low tech tool making for green woodworkers, focusing on accessible propane forging techniques including tempering tool steel by eye. The theory and processes of metalworking to make edge tools will be discussed.

We’ll start with a hook and then make a series of small projects to cover the basic skills, leading up to a slöjd knife and a gouge. Students will be able to customize their blades and handles to suit their needs and preferences within the parameters of the class projects.

Students will come away with a basic understanding of tool steel selection, tool making, attaching wooden handles and sharpening. Some simple sheath making and safe knife skills training will also be included. During the class, Kenneth will be assisting Lucian and teaching sharpening, knife skills and sheath making.

- finished for 2024 -

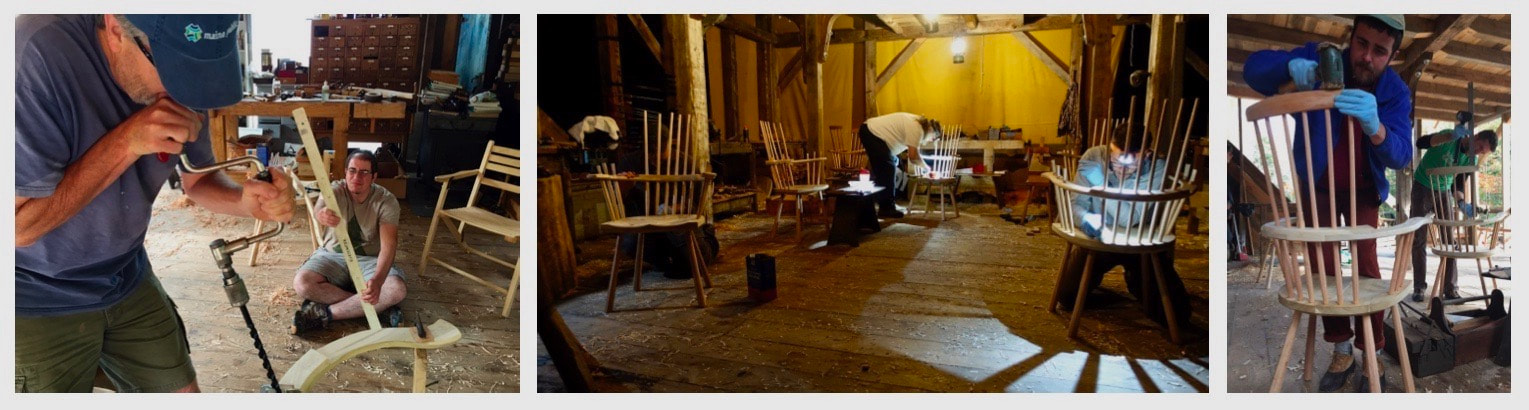

3. MACFAT/Make a Chair from a Tree (Post and Rung ladder back chair making);

fundamental green woodworking skills

May 4th - 11th, 2024 - 8 days

exertion level 2+ or 3 - materials fee: $55

$ 1,160 + $ 55 = $ 1,215.00 total

Using a minimal assortment of hand tools, students will learn how to craft and assemble this

elegant, lightweight, durable, and very comfortable chair. This is the chair and the class that Jennie Alexander is known for. Kenneth learned this chair from Drew Langsner, who learned and collaborated with Jennie A. and Dave Sawyer, teaching together at Country Workshops over the years. Kenneth in turn has been teaching this style of green wood post and rung chair making to beginning woodworkers since 2004.

This project is a wonderful introduction to a straightforward and simple form of chair making,

it teaches foundational techniques and skills that are used in making more advanced chairs and furniture. We recommend that students start with this class before building the Welsh Windsor chair.

The post and rung chair design is called a ladder-back because the back slats resemble the rungs of a ladder. It has also been called a mule ear because the tips of the back posts are reminiscent of ears. Chairs of this design were an inspiration to the Shakers who appreciated their utilitarian simplicity and lack of ornamentation.

The workshop begins with students learning how to select green logs and then to rive (or split) chair parts with a froe and club. Because we will be working with a freshly felled tree, this type of green woodworking offers a direct connection to the materials used and to an older, more sculptural way of working wood.

The riven posts (chair legs) and rungs are shaped with a draw knife and a spoke shave on a shave horse. Rear posts are steam bent onto a form to create the proper curve for the chair back. Rectangular mortises are chopped into the air dried posts with a mortising chisel, and cylindrical mortises are drilled by hand. Tenons are sized and cut on the rungs by hand. We take advantage of dissimilar moisture content between the air dried posts and the kiln dried rungs to help guarantee a tightening of the joinery from natural shrinkage of the wood as it dries. To fashion the seat, students will learn to weave with twisted natural rush. Finally, the back slats are shaped, steam bent, fitted and pinned in place with small hardwood pins.

Tool use, safety and sharpening will be thoroughly demonstrated and wood finishing will be addressed.

Students will have their red oak chairs assembled and the seats woven by the end of our class time. New for 2024 - We have added a day to the over-all length of this class in order to better allow for proper instruction and completion of seat weaving. In our experience, the weaving takes a full day for most students. Oiling or finishing the chair will need to be completed after the end of the workshop, once the chair has thoroughly dried.

3. MACFAT/Make a Chair from a Tree (Post and Rung ladder back chair making);

fundamental green woodworking skills

May 4th - 11th, 2024 - 8 days

exertion level 2+ or 3 - materials fee: $55

$ 1,160 + $ 55 = $ 1,215.00 total

Using a minimal assortment of hand tools, students will learn how to craft and assemble this

elegant, lightweight, durable, and very comfortable chair. This is the chair and the class that Jennie Alexander is known for. Kenneth learned this chair from Drew Langsner, who learned and collaborated with Jennie A. and Dave Sawyer, teaching together at Country Workshops over the years. Kenneth in turn has been teaching this style of green wood post and rung chair making to beginning woodworkers since 2004.

This project is a wonderful introduction to a straightforward and simple form of chair making,

it teaches foundational techniques and skills that are used in making more advanced chairs and furniture. We recommend that students start with this class before building the Welsh Windsor chair.

The post and rung chair design is called a ladder-back because the back slats resemble the rungs of a ladder. It has also been called a mule ear because the tips of the back posts are reminiscent of ears. Chairs of this design were an inspiration to the Shakers who appreciated their utilitarian simplicity and lack of ornamentation.

The workshop begins with students learning how to select green logs and then to rive (or split) chair parts with a froe and club. Because we will be working with a freshly felled tree, this type of green woodworking offers a direct connection to the materials used and to an older, more sculptural way of working wood.

The riven posts (chair legs) and rungs are shaped with a draw knife and a spoke shave on a shave horse. Rear posts are steam bent onto a form to create the proper curve for the chair back. Rectangular mortises are chopped into the air dried posts with a mortising chisel, and cylindrical mortises are drilled by hand. Tenons are sized and cut on the rungs by hand. We take advantage of dissimilar moisture content between the air dried posts and the kiln dried rungs to help guarantee a tightening of the joinery from natural shrinkage of the wood as it dries. To fashion the seat, students will learn to weave with twisted natural rush. Finally, the back slats are shaped, steam bent, fitted and pinned in place with small hardwood pins.

Tool use, safety and sharpening will be thoroughly demonstrated and wood finishing will be addressed.

Students will have their red oak chairs assembled and the seats woven by the end of our class time. New for 2024 - We have added a day to the over-all length of this class in order to better allow for proper instruction and completion of seat weaving. In our experience, the weaving takes a full day for most students. Oiling or finishing the chair will need to be completed after the end of the workshop, once the chair has thoroughly dried.

4. Hand Hewn Greenwood Bowl Carving; green woodworking, hand-tool work

June 10th - 14th, 2024 - 5 days

exertion level 2+, materials fee: $25

$ 725 + $25 = $ 750 total

We’ll delve into the reductive process in our Greenwood Bowl Carving class and learn how satisfying the process of carving out a bowl from a rough section of a newly felled tree can be.

Unlike lathe-turning, hewing a bowl by hand offers wider variation in terms of shapes and symmetry.

We’ll use a froe to split the birch log, then an axe, adze, gouges, spoke shaves and slöjd knives to gradually refine the size and shapes of our wooden vessels. During this thorough five day class, we will explore proper tree selection, layout and design, tool selection, various holding devices, decorative carving, wood finishing, and also edge tool use, care and sharpening.

2024 - based on our experience with this class in previous years, we have chosen to expand it in 2024 by adding a day. Therefore if time allows, students will be led through the process of making a shallow wooden platter and / or shown some basics of decorative carving & encouraged to give it a try.

Participants will come away with instructions on how best to dry their hand hewn bowls, as well as thorough information about the process and materials of oil finishing once their pieces have dried.

June 10th - 14th, 2024 - 5 days

exertion level 2+, materials fee: $25

$ 725 + $25 = $ 750 total

We’ll delve into the reductive process in our Greenwood Bowl Carving class and learn how satisfying the process of carving out a bowl from a rough section of a newly felled tree can be.

Unlike lathe-turning, hewing a bowl by hand offers wider variation in terms of shapes and symmetry.

We’ll use a froe to split the birch log, then an axe, adze, gouges, spoke shaves and slöjd knives to gradually refine the size and shapes of our wooden vessels. During this thorough five day class, we will explore proper tree selection, layout and design, tool selection, various holding devices, decorative carving, wood finishing, and also edge tool use, care and sharpening.

2024 - based on our experience with this class in previous years, we have chosen to expand it in 2024 by adding a day. Therefore if time allows, students will be led through the process of making a shallow wooden platter and / or shown some basics of decorative carving & encouraged to give it a try.

Participants will come away with instructions on how best to dry their hand hewn bowls, as well as thorough information about the process and materials of oil finishing once their pieces have dried.

5. Easy Peasy Chair Making, Bill Coperthwaite’s 4 board chair;

fundamentals of hand-tool use & design

June 20th - 23rd, 2024 - 4 days

exertion level 2, materials fee: $ 75

$ 580 + $ 75 = $ 655 total

We are excited to offer this new 4 day workshop; it is by far our most accessible and basic chair making class. We’ll be working with dimensional lumber and hand tools to build a 4 board chair based on an astute and simple design by Bill Coperthwaite.

Building this chair constitutes an excellent lesson in fundamental hand work, as we’ll use just human-powered hand tools, pine boards and (metal) wood screws to construct them. Proper wood selection, tool sharpening and care, plus finishing with milk paint and tung oil will also be covered in the class.

Bill Coperthwaite, our great mentor and late friend, spent years perfecting the design and the construction techniques for this simple workhorse of a chair. We have a number of them around the shop in use constantly - they provide lightweight, stable, fun and comfortable seating. One of Bill’s greatest wishes was to encourage people to make things which they need and use every day. He valued simple, utilitarian projects above almost anything, and he believed that these kinds of democratic designs can empower people to live more simply and happily.

Students in this chair making class will learn to use patterns and lay out their chair pieces, which they’ll cut from milled white pine boards using hand saws. Once the parts have been cut and shaped, the straightforward joinery is solidly held together with wood screws.

There will be time to carve facets and decorative textures to enhance the surfaces and edges of these simple chairs.

Participants will learn to use draw knives, hand saws, chisels, scorps, spoke shaves, slöjd knives and block planes.

Check out more information about Bill and his work at www.insearchofsimplicity.net

This sentence is a link to our blog entry about Bill’s democratic designs.

fundamentals of hand-tool use & design

June 20th - 23rd, 2024 - 4 days

exertion level 2, materials fee: $ 75

$ 580 + $ 75 = $ 655 total

We are excited to offer this new 4 day workshop; it is by far our most accessible and basic chair making class. We’ll be working with dimensional lumber and hand tools to build a 4 board chair based on an astute and simple design by Bill Coperthwaite.

Building this chair constitutes an excellent lesson in fundamental hand work, as we’ll use just human-powered hand tools, pine boards and (metal) wood screws to construct them. Proper wood selection, tool sharpening and care, plus finishing with milk paint and tung oil will also be covered in the class.

Bill Coperthwaite, our great mentor and late friend, spent years perfecting the design and the construction techniques for this simple workhorse of a chair. We have a number of them around the shop in use constantly - they provide lightweight, stable, fun and comfortable seating. One of Bill’s greatest wishes was to encourage people to make things which they need and use every day. He valued simple, utilitarian projects above almost anything, and he believed that these kinds of democratic designs can empower people to live more simply and happily.

Students in this chair making class will learn to use patterns and lay out their chair pieces, which they’ll cut from milled white pine boards using hand saws. Once the parts have been cut and shaped, the straightforward joinery is solidly held together with wood screws.

There will be time to carve facets and decorative textures to enhance the surfaces and edges of these simple chairs.

Participants will learn to use draw knives, hand saws, chisels, scorps, spoke shaves, slöjd knives and block planes.

Check out more information about Bill and his work at www.insearchofsimplicity.net

This sentence is a link to our blog entry about Bill’s democratic designs.

6. Small Greenwood Projects; fundamental hand-tool skills & green woodworking

June 29th & 30th, 2024 - 2 days

exertion level - 1

materials fee - none

$ 290 tuition + no materials fee = $ 290.00 total

This course encompasses the heart of coursework here at the Maine Coast Craft School. It’s our most foundational and introductory class where Kenneth teaches essential handwork skills, the bedrock of green woodworking.

This class could also be called Green Woodworking 101, although the unique projects can be enjoyed and useful to highly skilled carvers or educators looking to teach others as well.

We’ll be using two core hand tools, the sloyd knife (‘sloyd’ is Swedish for handcraft) & also a carving axe. We will develop hand and knife skills while carving projects such as butter spreaders, wall-mounted coat hooks made from limb crooks, Shinto inspired foxes and pine whorl whisks. All on a convenient weekend schedule.

skills learned:

- understanding wood fiber/grain

- understanding theory of sharpness in broad terms

- intro to sharpening edge tools - specifically essential/primary edge tools (sloyd knife & carving axe)

- safety: proper technique to keep oneself safe while using sharp tools

- hands-on projects to apply & understand basic concepts in an experiential way

June 29th & 30th, 2024 - 2 days

exertion level - 1

materials fee - none

$ 290 tuition + no materials fee = $ 290.00 total

This course encompasses the heart of coursework here at the Maine Coast Craft School. It’s our most foundational and introductory class where Kenneth teaches essential handwork skills, the bedrock of green woodworking.

This class could also be called Green Woodworking 101, although the unique projects can be enjoyed and useful to highly skilled carvers or educators looking to teach others as well.

We’ll be using two core hand tools, the sloyd knife (‘sloyd’ is Swedish for handcraft) & also a carving axe. We will develop hand and knife skills while carving projects such as butter spreaders, wall-mounted coat hooks made from limb crooks, Shinto inspired foxes and pine whorl whisks. All on a convenient weekend schedule.

skills learned:

- understanding wood fiber/grain

- understanding theory of sharpness in broad terms

- intro to sharpening edge tools - specifically essential/primary edge tools (sloyd knife & carving axe)

- safety: proper technique to keep oneself safe while using sharp tools

- hands-on projects to apply & understand basic concepts in an experiential way

7. Making a John Brown inspired vernacular Windsor chair; hand-tool chair making

July 7th - 13th, 2024 - 7 days

exertion level 2+ or 3 - materials fee: $ 120

$ 1,015 + $ 120 = $ 1,135.00 total

We will learn to make and assemble a Welsh style vernacular Windsor in this seven day class. The chairs which Kenneth builds (and the way he teaches students to to build them) are based on the unique design and techniques he learned while he was an apprentice with the late John Brown, the self-taught Welsh chair maker.

A pre-requisite for this class is the MACFAT/ Post and Rung Ladder Back Chair class.

Using hand tools, we’ll shape and assemble chair parts, working with both green and air-dried hardwoods. Some parts will be roughed out ahead of time (although this is not a kit) in order to allow for time constraints and various student skill levels.

All necessary specialized chair-making tools will be available for use and materials are all provided.

This is a very full learning experience and students will need to oil or otherwise finish their chairs after the conclusion of the class.

Students will need to be able to transport their chairs home after class.

(finished chairs measure 28” wide, 43” tall, 23” deep.)

July 7th - 13th, 2024 - 7 days

exertion level 2+ or 3 - materials fee: $ 120

$ 1,015 + $ 120 = $ 1,135.00 total

We will learn to make and assemble a Welsh style vernacular Windsor in this seven day class. The chairs which Kenneth builds (and the way he teaches students to to build them) are based on the unique design and techniques he learned while he was an apprentice with the late John Brown, the self-taught Welsh chair maker.

A pre-requisite for this class is the MACFAT/ Post and Rung Ladder Back Chair class.

Using hand tools, we’ll shape and assemble chair parts, working with both green and air-dried hardwoods. Some parts will be roughed out ahead of time (although this is not a kit) in order to allow for time constraints and various student skill levels.

All necessary specialized chair-making tools will be available for use and materials are all provided.

This is a very full learning experience and students will need to oil or otherwise finish their chairs after the conclusion of the class.

Students will need to be able to transport their chairs home after class.

(finished chairs measure 28” wide, 43” tall, 23” deep.)

8. Hanging Lidded Salt Box; fundamental handcraft and hand-tool skills

July 19th - 21st, 2024 - 3 days

exertion level 1, materials fee: $ 0

$ 435 + $ 15 = $ 450.00 total

This type of wooden, lidded box might be familiar, since they are historically quite common as containers for wooden matches, salt or other small household items. The box can be hung on a wall or set on a shelf or counter, depending on what it will contain and where it will be used.

This class will introduce students to essential and accessible hand-tool woodworking. The simple, small box project will teach participants about layout, design, wood selection and hand tool use and care.

We’ll use local white pine and the box will be assembled using a few small nails and small hardwood pins for the hinged lid.

Once the box has been assembled, we’ll learn about milk paint and also work on decorative carving skills, since this little box is so agreeable to customization with clever embellishment.

As we build this remarkably useful item, students will gain valuable knowledge and hand-tool skills, which are definitely transferable to all sorts of future woodworking projects.

We’re very excited to offer this fun new workshop for the first time in our class line-up.

July 19th - 21st, 2024 - 3 days

exertion level 1, materials fee: $ 0

$ 435 + $ 15 = $ 450.00 total

This type of wooden, lidded box might be familiar, since they are historically quite common as containers for wooden matches, salt or other small household items. The box can be hung on a wall or set on a shelf or counter, depending on what it will contain and where it will be used.

This class will introduce students to essential and accessible hand-tool woodworking. The simple, small box project will teach participants about layout, design, wood selection and hand tool use and care.

We’ll use local white pine and the box will be assembled using a few small nails and small hardwood pins for the hinged lid.

Once the box has been assembled, we’ll learn about milk paint and also work on decorative carving skills, since this little box is so agreeable to customization with clever embellishment.

As we build this remarkably useful item, students will gain valuable knowledge and hand-tool skills, which are definitely transferable to all sorts of future woodworking projects.

We’re very excited to offer this fun new workshop for the first time in our class line-up.

9. Maine Gum Boxes & Decorative Chip Carving with Kenneth Kortemeier & guest instructor Daniel Clay;

green woodworking, hand-tool skills, precision carving

July 29 - August 3, 2024 - 6 days

materials fee - $ 25.00

exertion level - 1

$ 870 + $ 25 = $ 895.00

Book boxes, gum boxes, or gum books — by any name these are lovely, handmade objects for holding precious things, about the size and shape of a book, and often made to be given as gifts. Gum boxes are a Maine Northwoods tradition with historical examples dating anywhere from the mid 1800s until about 1920. Craftsman Jögge Sundqvist showed us how these boxes were often made to hold the family bible or other precious books in Sweden. The Maine State museum and also the Patten Lumberman’s Museum have wonderful collections of antique spruce gum boxes from the 1800s, all made in the same fashion as the ones from Scandinavia. We are once again offering this class to highlight and celebrate the regional handcraft traditions brought to Maine by immigrant craftspeople.

Here’s a link to a nice article about the history of these boxes and spruce gum in America:

https://northernwoodlands.org/knots_and_bolts/remembering-spruce-gum

The boxes we will make are a regional variation on the Northern European tradition. Guest instructor Daniel Clay will be teaching the decorative carving skills portion of this class alongside Kenneth, who will be leading the box construction work.

Daniel recently published his first book, available here.

It's called “Chip Carving, Techniques For Carving Beautiful Patterns By Hand”.

It's a great read and would be good preparation for this class.

This is more of a carving project than a typical box-making workshop, as these classic boxes are made by boring and carving out the interior of a wide length of wood, resulting in no joinery in the four main sides of the box. The top and bottom are separate pieces, let into the interior walls, the top joint is a sliding dovetail and the bottom is dadoed. The outside walls of the box are planed and smoothed by hand once the inside has been hollowed, giving the walls a consistent thickness throughout. The outsides of many historical examples have been shaped to resemble books and students can go that route too if they choose.

In keeping with traditional materials and techniques, we’ll create our book boxes of pine or birch wood during the first part of this six day course. We’ll occasionally break from the work of building boxes in order to practice decorative carving techniques with Daniel. Once the boxes are completed and after students have had enough chip carving instruction and practice, we will design and carve a decorative pattern into our gum boxes. We’ll be using only hand-tools throughout the process, the same hand-tools that were historically used for these popular, regionally produced boxes well over a hundred years ago.

skills learned:

- boring holes by hand with a T-auger bit and a bit & brace

- using various edge tools such as a drawknife, sloyd knife, spoke shave, block plane & gouges to remove stock

- hand carving a housed dado or groove to fit top and bottom of the box

- using detail knives for decorative chip carving

green woodworking, hand-tool skills, precision carving

July 29 - August 3, 2024 - 6 days

materials fee - $ 25.00

exertion level - 1

$ 870 + $ 25 = $ 895.00

Book boxes, gum boxes, or gum books — by any name these are lovely, handmade objects for holding precious things, about the size and shape of a book, and often made to be given as gifts. Gum boxes are a Maine Northwoods tradition with historical examples dating anywhere from the mid 1800s until about 1920. Craftsman Jögge Sundqvist showed us how these boxes were often made to hold the family bible or other precious books in Sweden. The Maine State museum and also the Patten Lumberman’s Museum have wonderful collections of antique spruce gum boxes from the 1800s, all made in the same fashion as the ones from Scandinavia. We are once again offering this class to highlight and celebrate the regional handcraft traditions brought to Maine by immigrant craftspeople.

Here’s a link to a nice article about the history of these boxes and spruce gum in America:

https://northernwoodlands.org/knots_and_bolts/remembering-spruce-gum

The boxes we will make are a regional variation on the Northern European tradition. Guest instructor Daniel Clay will be teaching the decorative carving skills portion of this class alongside Kenneth, who will be leading the box construction work.

Daniel recently published his first book, available here.

It's called “Chip Carving, Techniques For Carving Beautiful Patterns By Hand”.

It's a great read and would be good preparation for this class.

This is more of a carving project than a typical box-making workshop, as these classic boxes are made by boring and carving out the interior of a wide length of wood, resulting in no joinery in the four main sides of the box. The top and bottom are separate pieces, let into the interior walls, the top joint is a sliding dovetail and the bottom is dadoed. The outside walls of the box are planed and smoothed by hand once the inside has been hollowed, giving the walls a consistent thickness throughout. The outsides of many historical examples have been shaped to resemble books and students can go that route too if they choose.

In keeping with traditional materials and techniques, we’ll create our book boxes of pine or birch wood during the first part of this six day course. We’ll occasionally break from the work of building boxes in order to practice decorative carving techniques with Daniel. Once the boxes are completed and after students have had enough chip carving instruction and practice, we will design and carve a decorative pattern into our gum boxes. We’ll be using only hand-tools throughout the process, the same hand-tools that were historically used for these popular, regionally produced boxes well over a hundred years ago.

skills learned:

- boring holes by hand with a T-auger bit and a bit & brace

- using various edge tools such as a drawknife, sloyd knife, spoke shave, block plane & gouges to remove stock

- hand carving a housed dado or groove to fit top and bottom of the box

- using detail knives for decorative chip carving

10. Carve your Magic Loving Gift - the Swedish Folk Art Tradition of the Carved Distaff with guest instructor Jögge Sundqvist; handcraft skills, precision carving & knife grips

August 12th - 16th, 2024 - 5 days

exertion level 1, materials fee: $ 20

$ 1,000 + $ 20 = $ 1,020.00 total

- tuition for this class is $ 200 per day (as opposed to our usual $130 per day), and we are adding an additional student spot, so that we may pay our guest instructor appropriately and cover his travel costs from Sweden

Jögge works with hand tools in the self-sufficient Scandinavian fine craft tradition.

He learned at age 4 to use the knife and the axe from his father, Wille Sundqvist. Jögge was in the fine woodcraft program at the Vindeln Folkhighscool in 1982-84. He makes stools, chairs, cupboards, knives, spoons, sculpture and shelves, with all surfaces carved or hand-planed and painted with artist’s oil colors. He has run a professional small business called s u r o l l e since 1999, where he makes fine crafts, teaches and writes books. His newest book, Karvsnitt, has just been published in English this past July and is available at Lost Art Press.

We’re so excited to have Jögge return to the Maine Coast Craft School.

He will teach us all about carving a distaff, a wooden implement used in the process of spinning flax or wool fibers. A charming Swedish story about this tool is connected to courtship; if one fancied a particular partner, they would carve a distaff to demonstrate their handcraft and design skills and to hopefully impress the recipient. If the object was up to the mark, and the proffered gift was accepted, the engagement was on.

Jögge’s class will have a focus on Swedish Folk Art, which he grew up surrounded by and practicing. He’ll include lessons in precision carving, special knife grips, and demonstrate his special chip carving with Magic Patterns, to help win that sweetheart for certain.

* Please note - Tuition for this class is different than our normal fee, it costs $200 per day. *

August 12th - 16th, 2024 - 5 days

exertion level 1, materials fee: $ 20

$ 1,000 + $ 20 = $ 1,020.00 total

- tuition for this class is $ 200 per day (as opposed to our usual $130 per day), and we are adding an additional student spot, so that we may pay our guest instructor appropriately and cover his travel costs from Sweden

Jögge works with hand tools in the self-sufficient Scandinavian fine craft tradition.

He learned at age 4 to use the knife and the axe from his father, Wille Sundqvist. Jögge was in the fine woodcraft program at the Vindeln Folkhighscool in 1982-84. He makes stools, chairs, cupboards, knives, spoons, sculpture and shelves, with all surfaces carved or hand-planed and painted with artist’s oil colors. He has run a professional small business called s u r o l l e since 1999, where he makes fine crafts, teaches and writes books. His newest book, Karvsnitt, has just been published in English this past July and is available at Lost Art Press.

We’re so excited to have Jögge return to the Maine Coast Craft School.

He will teach us all about carving a distaff, a wooden implement used in the process of spinning flax or wool fibers. A charming Swedish story about this tool is connected to courtship; if one fancied a particular partner, they would carve a distaff to demonstrate their handcraft and design skills and to hopefully impress the recipient. If the object was up to the mark, and the proffered gift was accepted, the engagement was on.

Jögge’s class will have a focus on Swedish Folk Art, which he grew up surrounded by and practicing. He’ll include lessons in precision carving, special knife grips, and demonstrate his special chip carving with Magic Patterns, to help win that sweetheart for certain.

* Please note - Tuition for this class is different than our normal fee, it costs $200 per day. *

11. Coopering Small Wooden Buckets; hand-tool skills & design

August 24 - 29, 2024 - 6 days

exertion level 1, materials fee: $ 45

$ 870 + $ 45 = $ 915.00 total

Explore the art of coopering by making a classic wooden bucket in this six day class. Finished buckets will be about 10” diameter by 10 or 12” tall. This is one of the few projects at our school where the wood (for the staves or sides) of the bucket is air dried, not green.

Starting with roughed-out, air dried stock, we’ll carefully lay out the bevels and taper of the upright wall pieces, called staves, shaping the bevels with a large wooden jointers plane.

The staves will be made of clear, vertical grain pine.

We’ll use temporary metal bands, and a cooper’s draw shave to roughly shape the inside of the staves into a curve.

We’ll spend time refining the bevels until we achieve water-tight joints between all the staves.

Small wooden pins are used for alignment once the bevels are completed.

The inside of the joined staves will be finished into a smooth-walled cylinder using a curved sole cooper’s plane.

Next, a specialized tool called a croze is used to cut a dado which captures and houses the edge of the carved pine bottom.

The final steps involve making a steam bent oak handle and fitting hoops made from small diameter green wood saplings that are notched and fitted for the outside of the coopered bucket.

August 24 - 29, 2024 - 6 days

exertion level 1, materials fee: $ 45

$ 870 + $ 45 = $ 915.00 total

Explore the art of coopering by making a classic wooden bucket in this six day class. Finished buckets will be about 10” diameter by 10 or 12” tall. This is one of the few projects at our school where the wood (for the staves or sides) of the bucket is air dried, not green.

Starting with roughed-out, air dried stock, we’ll carefully lay out the bevels and taper of the upright wall pieces, called staves, shaping the bevels with a large wooden jointers plane.

The staves will be made of clear, vertical grain pine.

We’ll use temporary metal bands, and a cooper’s draw shave to roughly shape the inside of the staves into a curve.

We’ll spend time refining the bevels until we achieve water-tight joints between all the staves.

Small wooden pins are used for alignment once the bevels are completed.

The inside of the joined staves will be finished into a smooth-walled cylinder using a curved sole cooper’s plane.

Next, a specialized tool called a croze is used to cut a dado which captures and houses the edge of the carved pine bottom.

The final steps involve making a steam bent oak handle and fitting hoops made from small diameter green wood saplings that are notched and fitted for the outside of the coopered bucket.

12. Ornate carved Tramp Art box; hand-tool skills & design

September 14 - 18, 2024 - 5 days

exertion level 1, materials fee: $ 45

$ 725 + $ 45 = $ 770.00 total

If you enjoy carving and whittling, this may be a new way to investigate that interest and apply your skills. This work is similar to chip carving and requires only a few tools, mostly a detail carving knife.

During this workshop, we will be exploring an obscure form of American vernacular folk art. This style of decorative carving was popular with and crafted mostly by northern European immigrants from the 1870’s up until about the 1940’s. It was given the misnomer Tramp Art by antiques dealers in the 1950s as a way to build mystique and increase market value.

We’ll learn more history around the materials typically used, namely discarded cigar boxes and the wood from fruit packing crates. We will see several examples and images of how these complicated, decoratively carved items were utilized - from fancy sewing boxes to remarkable picture frames to entire bedroom sets of elaborately carved furniture.

Students will design and build their own Tramp Art box after learning the straightforward chip carving techniques. The classic notched, stacked layers of thin mahogany boards are used to decorate and elevate cast-off wooden cigar boxes.

Students will also come to understand the repeated puzzle pieces of the “Crown of Thorns” style of folk art, made with a visually enigmatic three-dimensional structure which baffles the eye, until one knows the way that the puzzle fits together.

Hand sawing, design and knife skills will be worked on and gained in this class. Oil finishing and painting will be discussed as well. We’ll keep our hands busy and we won’t let good materials go to waste in this fascinating class all about an authentically American vernacular folk art.

September 14 - 18, 2024 - 5 days

exertion level 1, materials fee: $ 45

$ 725 + $ 45 = $ 770.00 total

If you enjoy carving and whittling, this may be a new way to investigate that interest and apply your skills. This work is similar to chip carving and requires only a few tools, mostly a detail carving knife.

During this workshop, we will be exploring an obscure form of American vernacular folk art. This style of decorative carving was popular with and crafted mostly by northern European immigrants from the 1870’s up until about the 1940’s. It was given the misnomer Tramp Art by antiques dealers in the 1950s as a way to build mystique and increase market value.

We’ll learn more history around the materials typically used, namely discarded cigar boxes and the wood from fruit packing crates. We will see several examples and images of how these complicated, decoratively carved items were utilized - from fancy sewing boxes to remarkable picture frames to entire bedroom sets of elaborately carved furniture.

Students will design and build their own Tramp Art box after learning the straightforward chip carving techniques. The classic notched, stacked layers of thin mahogany boards are used to decorate and elevate cast-off wooden cigar boxes.

Students will also come to understand the repeated puzzle pieces of the “Crown of Thorns” style of folk art, made with a visually enigmatic three-dimensional structure which baffles the eye, until one knows the way that the puzzle fits together.

Hand sawing, design and knife skills will be worked on and gained in this class. Oil finishing and painting will be discussed as well. We’ll keep our hands busy and we won’t let good materials go to waste in this fascinating class all about an authentically American vernacular folk art.

"Power machines are unfriendly for they are very noisy and make a lot of unpleasant dust.

Craft woodworking should be a creative activity, with the practitioners as artists.

Surrounded by ugly, noisy, dusty machines the woodworker does not have the environment in which to do good work."

- John Brown, chair maker